In this leg of the tour we headed North from Adelaide. The first stop was hardly any distance at all, as we visited a Smiths Crisps plant in the northern outskirts of the city. Food processing plants fall into two categories: either you come out swearing that you'll never eat their products again, or not. This was the second kind, though a look at the bulk delivery of cooking oils suggests that it might be healthier to limit one's intake. They make crisps and various starchy snacks too.

In this leg of the tour we headed North from Adelaide. The first stop was hardly any distance at all, as we visited a Smiths Crisps plant in the northern outskirts of the city. Food processing plants fall into two categories: either you come out swearing that you'll never eat their products again, or not. This was the second kind, though a look at the bulk delivery of cooking oils suggests that it might be healthier to limit one's intake. They make crisps and various starchy snacks too.Back in the bus, we headed north about 200km to Port Pirie, the home of Nyrstar Ltd. This is a major refiner of lead, zinc, copper and precious metals. I have a beautiful aerial picture of the plant, but can't seem to get it down here. No matter- it's not really as beautiful as it is made to appear.

The process is as follows. (Non- Chemical Engineers switch off)

A feedstock made up mainly of lead concentrate is fed into a sintering machine. Other raw materials may be added, including iron, silica, limestone flux, coke, soda ash, pyrite, zinc, caustic, and particulates gathered from pollution control devices. The sintering feed, along with coke, is fed into a blast furnace for reducing, where the carbon also acts as a fuel and smelts the lead-containing materials. The molten lead flows to the bottom of the furnace, where four layers form: “speiss” (the lightest material, basically arsenic and antimony), “matte” (copper sulfide and other metal sulfides), blast furnace slag (primarily silicates), and lead bullion (98% by weight). All layers are then drained off. The speiss and matte are sold to copper smelters for recovery of copper and precious metals. The blast furnace slag, which contains zinc, iron, silica, and lime, is stored in piles and is partially recycled. Sulfur oxide emissions are generated in blast furnaces from small quantities of residual lead sulfide and lead sulfates in the ore.

The whole thing is a great deal more complex- the zinc is recovered by reducing the slag and copper is hydrometallurgically and then electrolytically refined. I've got the flow diagrams if anyone is interested. There is also significant production of silver and cadmium as byproducts.

The plant is the major employer locally and environmental concerns are very real. They have a campaign to reduce the lead concentration in the residents' blood to below 10ppb, for example. If it were a new plant, there's be a lot more protests. But they can't do without it.

This is a view which doesn't include the plant and does take in the Flinders ranges- but the weather was a bit poor for photography.

This is a view which doesn't include the plant and does take in the Flinders ranges- but the weather was a bit poor for photography. This was where the students were staying. It's a caravan park with cabins. In this particular case they did better than we did, because we were in a motel that was comprehensively dire- flooding toilets, home- wired electrics, the lot. However, I think it's better for esprit de corps ( and for behaviour in general) if staff and students stay in the same place. I'm not saying whose behaviour, by the way.....

This was where the students were staying. It's a caravan park with cabins. In this particular case they did better than we did, because we were in a motel that was comprehensively dire- flooding toilets, home- wired electrics, the lot. However, I think it's better for esprit de corps ( and for behaviour in general) if staff and students stay in the same place. I'm not saying whose behaviour, by the way.....

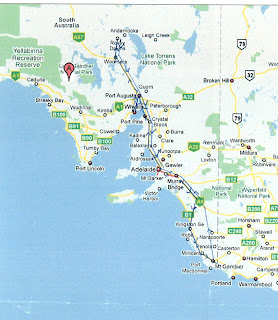

We headed next round the head of the Spencer Gulf, which is the big inlet you can see on the maps cutting into the centre of the South coast of Australia. This is the bridge across the head of the gulf.

The first plant we visited that day was the power station at Port Augusta.

This was a particularly good image of lofting and the application of the Chalk Ridge Formula. The Third Year will be exposed to it in Environmental Issues after the New Year.

This was a particularly good image of lofting and the application of the Chalk Ridge Formula. The Third Year will be exposed to it in Environmental Issues after the New Year.

And this is the station from a distance. I was surprised to hear that they haven't re-equipped with low-Nox burners. Their reason is the penalty on thermal efficiency, but I think the excuse is that the local coal is very low-sulphur anyway (and the population density around is extremely low!) Ash content, on the contrary, is very high and disposal is a major concern.

And this is the station from a distance. I was surprised to hear that they haven't re-equipped with low-Nox burners. Their reason is the penalty on thermal efficiency, but I think the excuse is that the local coal is very low-sulphur anyway (and the population density around is extremely low!) Ash content, on the contrary, is very high and disposal is a major concern.

Next stop was OneSteel at Whyalla. It's situated in this rather remote region because there's abundant iron ore in three separate deposits within 20 miles. It's brought in using hydrotransport in pipelines. They're very proud that it was a major site of Australian shipbuilding during the war (steel close, good deep water anchorages and as far from Japan as it's possible to be in Australia.) The corvette is memorial to this activity- completely dead now.

This was a particularly good image of lofting and the application of the Chalk Ridge Formula. The Third Year will be exposed to it in Environmental Issues after the New Year.

This was a particularly good image of lofting and the application of the Chalk Ridge Formula. The Third Year will be exposed to it in Environmental Issues after the New Year. And this is the station from a distance. I was surprised to hear that they haven't re-equipped with low-Nox burners. Their reason is the penalty on thermal efficiency, but I think the excuse is that the local coal is very low-sulphur anyway (and the population density around is extremely low!) Ash content, on the contrary, is very high and disposal is a major concern.

And this is the station from a distance. I was surprised to hear that they haven't re-equipped with low-Nox burners. Their reason is the penalty on thermal efficiency, but I think the excuse is that the local coal is very low-sulphur anyway (and the population density around is extremely low!) Ash content, on the contrary, is very high and disposal is a major concern.

Next stop was OneSteel at Whyalla. It's situated in this rather remote region because there's abundant iron ore in three separate deposits within 20 miles. It's brought in using hydrotransport in pipelines. They're very proud that it was a major site of Australian shipbuilding during the war (steel close, good deep water anchorages and as far from Japan as it's possible to be in Australia.) The corvette is memorial to this activity- completely dead now.

No comments:

Post a Comment